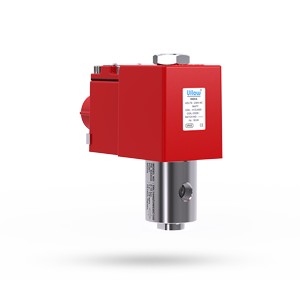

Gantry Solenoid Valve

Gantry Solenoid Valve

2/2 Solenoid Valve for Terminal / Gantry Automation (NC / NO) – DAR Series

This 2/2 Solenoid Valve from the DAR Series is specifically engineered for terminal and gantry automation applications. Designed for use with flammable and non-flammable liquids, it features durable construction, advanced sealing materials, and versatile coil options, making it reliable for high-demand operations in industrial environments.

Valve Specifications

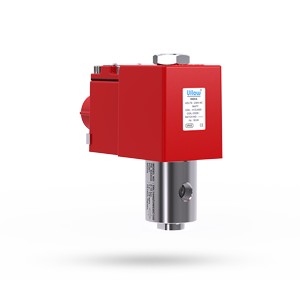

Port:

- 1/4” NPT(F)

Body Material:

- SS316 (Standard for high corrosion resistance)

- SS304 (Optional)

Seal & O-Ring Material:

- Viton GLT (Fluoroelastomer, designed for extreme temperature resistance)

Media Temperature Range:

- -30°C to 230°C

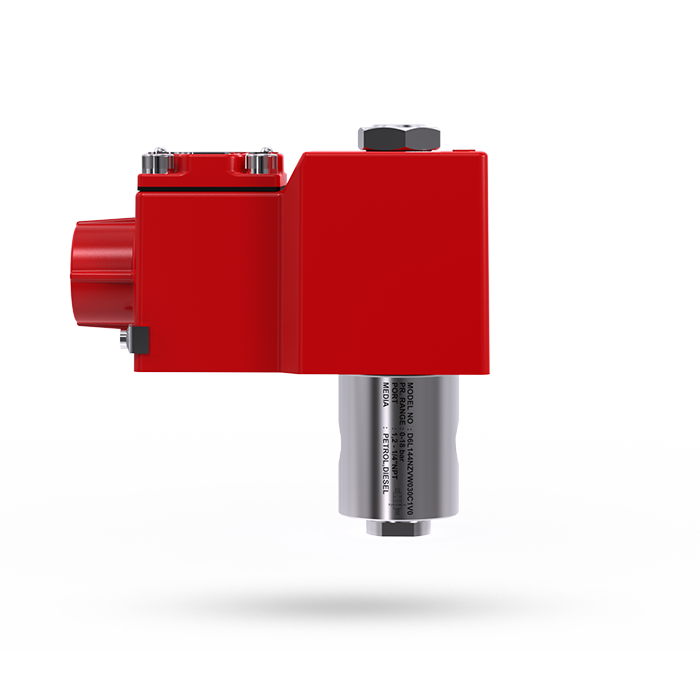

Media Compatibility:

- Petrol

- Diesel

- SKO (Superior Kerosene Oil)

- HSD (High-Speed Diesel)

Model Numbers:

- D6J146NNVW035C1V0

- D6J144NZVW030C1V0

Valve Position Options:

- Normally Closed (NC)

- Normally Open (NO)

Valve Type:

- 2/2 Direct Acting

Orifice Size:

- 3.5 mm (Model-specific)

- 3 mm (Model-specific)

Pressure Range:

- 0 to 21 bar (Model-specific)

- 0 to 18 bar (Model-specific)

Ambient Temperature:

- -20°C to 70°C

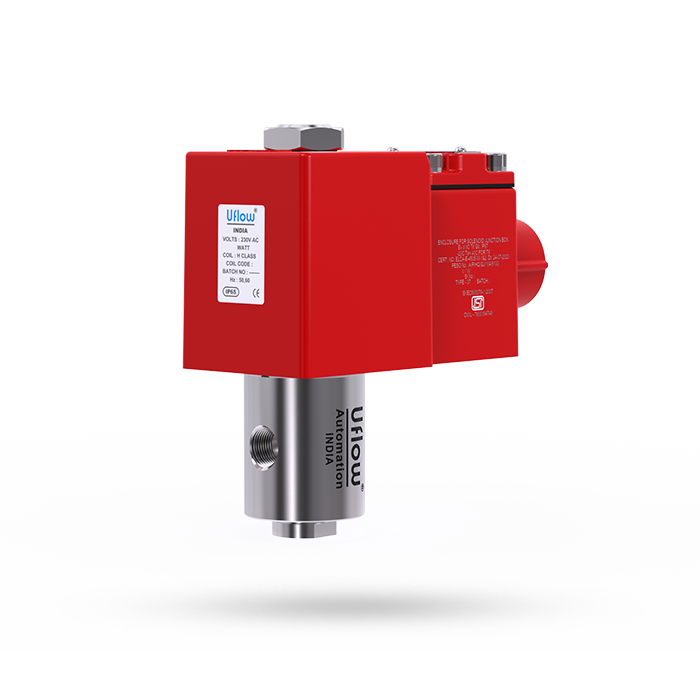

Coil Specifications

Coil Features:

- High reliability and unaffected by voltage surges.

- Coils are easy to replace and lockable in 4×90° positions or freely movable as required.

Coil Housing Options:

- IP65 Epoxy square coil for standard industrial use.

- IP65 Metallic round enclosure for additional protection.

- IP67 Flameproof enclosure for hazardous environments.

- IP68 Weatherproof enclosure for outdoor use in harsh conditions.

Operating Voltage:

- 230V AC

Power Consumption:

- 9W

Key Features

High-Temperature and Corrosion Resistance:

- Made of SS316 or SS304 and equipped with Viton GLT seals, the valve withstands temperatures up to 230°C and is ideal for corrosive and high-temperature environments.

Wide Pressure Range:

- Operates efficiently within pressure ranges up to 21 bar, catering to high-pressure applications.

Versatile Coil Housing Options:

- Multiple housing types ensure suitability for a variety of environments, from standard industrial setups to hazardous and outdoor conditions.

Direct Acting Design:

- Ensures immediate operation without requiring pressure differential, providing precise flow control.

Compact and Reliable:

- The valve’s compact design makes it ideal for terminal automation systems where space is limited but reliability is crucial.

Customizable Configurations:

- Available in Normally Closed (NC) and Normally Open (NO) variants to suit application-specific requirements.

Applications

Terminal Automation Systems:

- Designed for controlling the flow of fuel in storage and loading terminals.

Gantry Automation:

- Reliable operation in gantry systems managing petrol, diesel, and other fuels.

Petroleum and Chemical Industry:

- Handles high-temperature and highly flammable media like petrol, diesel, and kerosene.

Diesel and Oil Distribution Systems:

- Facilitates safe and efficient control of HSD and other oils.

High-Pressure Fuel Systems:

- Provides accurate flow control in fuel systems operating under high pressure.

Advantages

Safety-Oriented Design:

Flameproof and weatherproof coil options ensure safe operation in hazardous environments.Broad Temperature and Pressure Handling:

Operates across a wide range of temperatures (-30°C to 230°C) and pressures (up to 21 bar), making it adaptable for demanding applications.Durable and Corrosion Resistant:

High-quality SS316 construction and Viton GLT seals provide extended service life even in harsh conditions.Easy Maintenance:

Modular design allows for quick coil replacement and low downtime.

- It is recommended to use a filter in the inlet port to prevent debris and ensure smooth operation.

- Specifications are subject to change without prior notice to accommodate improved designs and performance.

This 2/2 Solenoid Valve from the DAR Series is a robust, high-performance solution for terminal automation, fuel systems, and other industrial applications requiring reliable flow control for petrol, diesel, and high-temperature media.