Solenoid Valve

Solenoid Valves for Industrial Applications

Solenoid valves are critical components for controlling the flow of fluids and gases in industrial settings. These valves use an electromechanical solenoid to open or close flow paths, offering precision and automation in fluid control systems. Below is a detailed overview of various solenoid valve types, their features, and applications:

1. Single Solenoid Valves

3/2 Single Solenoid Valve with Spring Return (NC/NO)

- Configuration: Three ports, two positions.

- Function: Switches between normally closed (NC) and normally open (NO) when energized.

- Mechanism: Spring return ensures the valve returns to its default position when de-energized.

5/2 Single Solenoid Valve with Spring Return (NC/NO)

- Configuration: Five ports, two positions.

- Function: Provides multiple flow paths, ideal for complex fluid circuits.

- Mechanism: Spring return to default state when solenoid is not powered.

3/2 & 5/2 Single Solenoid Namur Valve

- Standard: Namur compliant.

- Sizes: 1/4″ & 1/2″ BSP.

- Applications: Common in manufacturing, automation, and process control industries.

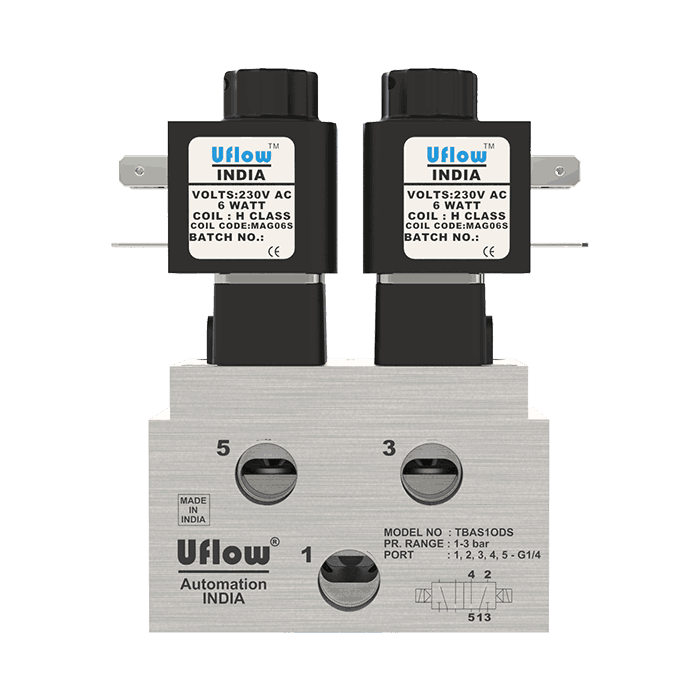

2. Double Solenoid Valves

Design & Construction

- Design: Spool with cartridge type construction.

- Media: Compressed air (filtered and lubricated).

- Body Material: Aluminium with epoxy square coil housing.

Operational Parameters

- Pressure Range: 2-10 Bar.

- Temperature: 5°C to 60°C.

- Flow Rates: 1/4″ – 1200 LPM, 1/2″ – 3500 LPM.

- Voltage Options: AC (12V, 24V, 110V, 230V), DC (12V, 24V).

- Power Consumption: 6W.

Valve Configurations

- 3/2 & 5/2 Double Solenoid Valve with Spring Return (NC/NO)

- 5/3 Double Solenoid Valve with Spring Center: Five ports, three positions, spring-centered for precise control.

3. Pilot Operated Piston Type Steam Solenoid Valves (HCP & HCA Series)

HCP Series

- Sizes: 1/2″ to 2″.

- Body Material: SS304 (optional SS316).

- Connection: BSP(F), NPT(F), Flange End.

- Seals: PTFE + Special Viton.

- Temperature: Up to 180°C.

- Pressure Range: 1.5 to 12 Bar.

- Media: Steam, hot fluids, air, water, gas, and chemicals.

HCA Series

- Sizes: 1/2″ to 2″.

- Seals: PTFE + NBR.

- Temperature Range: Up to 90°C.

- Pressure Range: 1.5 to 40 Bar.

- Applications: Ideal for industrial steam and high-pressure systems.

4. Pilot Operated Diaphragm Type Solenoid Valves (PCN Series)

Specifications

- Size Range: 3/8″ to 4″.

- Body Material: SS304 (optional SS316).

- Connection: BSP(F), NPT(F), Flange End.

- Seals: Nitrile (NBR), EPDM, Viton (FKM).

- Temperature Range: -30°C to 180°C.

- Pressure Range: 1.5 to 12 Bar, up to 20 kg for high pressure applications.

- Applications: Used in food and beverage, pharmaceuticals, chemicals, oil & gas, and water treatment industries.

5. Semi-Lift Diaphragm Operated Solenoid Valves (MCN & MBN Series)

Specifications

- Sizes: 3/8″ & 1/2″ (Forged Brass), 1/2″ to 2″ (Stainless Steel).

- Body Materials: SS304, SS316, Forged Brass.

- Types: Normally Closed (NC), Normally Open (NO).

- Seals: Nitrile (NBR), EPDM, Viton (FKM), PTFE.

- Temperature Range: -30°C to 180°C (media); -10°C to 70°C (ambient).

- Pressure Range: 0 to 10 Bar.

- Applications: Common in food industries, pharmaceuticals, chemical handling, and corrosive environments.

6. Gas Solenoid Valve (DAN Series)

Specifications

- Material: Aluminium Pressure Die Cast.

- Media Temperature Range: -30°C to 90°C.

- Circumstance Temperature: -10°C to 70°C.

- Media: Air, natural gas, town gas.

- Voltage Options: 110V AC, 230V AC.

- Power Consumption: 30W.

- Features: Adjustable flow, high reliability, quick-release initial flow, epoxy square coil housing.

- Standards: IEC-60335-1, EN-161.

- Applications: Ideal for gas control systems in industrial settings.

7. 2/2 Way Direct Acting Solenoid Valves (DAN, DCN & DBN Series)

Specifications

- Sizes: 1/8″ to 1/2″.

- Body Materials: Aluminium, SS304, SS316, Forged Brass.

- Seal Options: Nitrile (NBR), EPDM, Viton (FKM), Silicone.

- Media Temperature Range: -30°C to 180°C.

- Pressure Range: 0 to 150 Bar.

- Voltage Options: AC (24V, 110V, 230V), DC (12V, 24V).

- Applications: Suitable for food processing, pharmaceuticals, chemical systems, oil & gas, steam, HVAC, and water treatment.

8. 3/2 Way Direct Acting Solenoid Valves (TAN, TCN & TBN Series)

Specifications

- Sizes: 1/8″ to 1/2″.

- Body Materials: Aluminium, SS304, SS316, Forged Brass.

- Seal Options: Nitrile (NBR), EPDM, Viton (FKM).

- Media Temperature Range: -30°C to 180°C.

- Pressure Range: 0 to 10 Bar.

- Applications: Common in food processing, pharmaceutical production, chemical handling, oil & gas, steam systems, HVAC, and water treatment.

9. Auto Drain Valve – Uflow 2/2 Way Direct Acting Solenoid Valve (Normally Closed)

Specifications

- Port Size: 1/2″ BSP Thread.

- Body Material: CF8.

- Media Temperature Range: -30°C to 180°C.

- Seals: Nitrile (NBR), EPDM, Viton (FKM), SPL Viton.

- Timing: Adjustable from 1 min to 120 min cycle; 1 sec to 25 sec drain.

- Voltage: 230V AC.

- Power Consumption: 9W.

- Applications: Ideal for automated drainage in air, water, chemical, and gas applications.

10. Pilot Operated Auto Drain Valve

Uflow Pilot Operated High Flow Auto Drain Solenoid Valve (TCP Series)

This valve is designed for automatic drainage of condensates from compressed air systems and other industrial applications, offering high reliability, robust construction, and easy maintenance.

Key Features:

- Corrosion Resistance: Constructed from CF8 (Cast Stainless Steel), ensuring durability in harsh environments.

- High Reliability Coil: Voltage surge resistant, with flexible positioning.

- Adjustable Timing: Cycle time from 1 minute to 120 minutes, drain time from 1 second to 25 seconds.

- Energy Efficient: 9W power consumption across all voltage options.

Applications:

- Compressed Air Systems: Automatic condensate drainage.

Industrial Machinery & Chemical Systems: Removes moisture and contaminants to prevent damage.

11. Direct Acting Angle Solenoid Valve

Uflow 2/2 Way Direct Acting Angle Type Valve (NC)

This valve is designed for flow control in various industrial systems, ensuring reliable performance and precision in controlling air, water, chemicals, and gases.

Key Features:

- Durability: Made with superior corrosion-resistant steel for long-lasting performance.

- Efficient Coil Design: Surge-resistant, ensuring uninterrupted operation.

- Energy Efficient: Consumes 10W of power.

- Compact Design: Easy to install and maintain.

Applications:

- Flow Control: Ideal for air, water, chemical, and gas flow regulation in industrial processes.

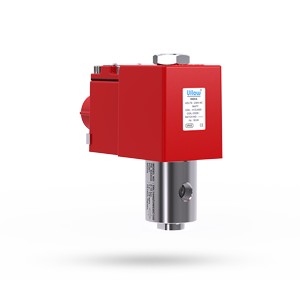

12. High Pressure Solenoid Valve

High-Pressure Pilot Operated Diaphragm Type Solenoid Valve (PBU Series)

A reliable high-pressure solenoid valve for air flow control in industries such as food, pharmaceuticals, and chemicals.

Key Features:

- Corrosion Resistance: Built with SS316L, CF8, and forged brass for durability.

- Voltage Surge Resistance: Ensures reliable performance even with fluctuating voltages.

- IP65 Epoxy Coil Housing: Provides protection against harsh environments.

- Energy Efficient: Low power consumption ranging from 6W to 11W depending on the voltage.

Applications:

- Food and Beverage, Pharmaceuticals, and Chemical Processing: Ensures sterile and efficient operation in demanding industries.

Compressed Air Systems: Ideal for high-pressure air regulation.

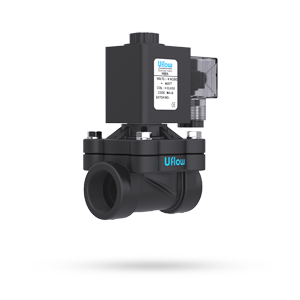

13. Nylon Semi Lift Diaphragm Operated Solenoid Valve

Uflow Nylon Semi Lift Diaphragm Solenoid Valve (NC/NO)

The Uflow Nylon Semi Lift Diaphragm Operated Solenoid Valve is designed to offer precise control for air, water, chemicals, and other media in industrial systems. Known for its durability and high-performance characteristics, this valve is ideal for environments where reliability and ease of maintenance are essential.

Specifications

- Port Size: 3/8″ to 2″

- End Connection: BSP (F), NPT (F), Flange

- Body Material: Nylon (Various grades depending on the media)

- Diaphragm Material: EPDM, Nitrile (NBR), Viton (FKM), or PTFE

- Media Temperature: -30°C to 120°C

- Circumstance Temperature: -10°C to 70°C

- Media Compatibility: Air, Water, Chemicals, Gas

Main Features

- Durability:

- Nylon body construction ensures a lightweight yet robust valve that stands up to corrosion, abrasion, and wear.

- The semi-lift diaphragm offers effective sealing and reliable operation over time.

- Efficient Flow Control:

- The diaphragm mechanism ensures smooth and consistent operation, minimizing the risk of sticking or jamming, even in challenging environments.

- Customizable Materials:

- Seals made from various materials (EPDM, Viton, PTFE) allow for compatibility with different media, making it versatile across industries.

- Energy Efficiency:

- Low power consumption, designed to operate efficiently, reducing operational costs.

- Easy Maintenance:

- Simple construction and replaceable components make maintenance straightforward, minimizing downtime and extending service life.

Operating Voltage & Power Consumption

- Voltage Options:

- 230V AC

- 24V DC

- 12V DC

- Power Consumption:

- 5W (AC), 4W (DC)

Applications

- Industrial Flow Control: For controlling the flow of air, water, or chemicals in production lines, and system regulation.

- Chemical Processing: Compatible with many types of aggressive chemicals, suitable for use in manufacturing plants.

- Water Treatment Plants: Ideal for water regulation and filtration systems.

- Food & Beverage: Meets sanitary requirements for food and beverage production lines, controlling water and other fluids in processes.

Key Benefits

- Corrosion Resistance: Nylon construction provides excellent resistance to corrosion and chemical degradation, making it ideal for use in harsh environments.

- Versatile Sealing Options: The ability to customize seals for different media ensures that the valve can be used across multiple industries.

- Space-Saving Design: The compact, lightweight design of the valve allows for easy integration into a variety of setups.

- Cost-Effective Operation: With low energy consumption and long service intervals, the valve offers a cost-effective solution for demanding applications.

The Uflow Nylon Semi Lift Diaphragm Operated Solenoid Valve is a high-quality and reliable solution for precise fluid control in industrial processes. Its durability, customizable options, and easy maintenance make it an excellent choice for industries such as food processing, water treatment, and chemical manufacturing.

14. 2 Way Control Solenoid Valve

Uflow 2 Way Control Solenoid Valve (NC/NO)

The Uflow 2-Way Control Solenoid Valve is designed for on/off control of media such as air, water, gas, and chemicals. With a focus on reliability and efficiency, this valve provides precise control in various industrial applications.

Specifications

- Port Size: 1/8″ to 1/2″

- End Connection: BSP (F), NPT (F)

- Body Material: SS304, SS316, Aluminium, Brass

- Seal Material: Nitrile (NBR), Viton (FKM), EPDM

- Temperature Range: -30°C to 150°C

- Pressure Range: 0 to 120 Bar

- Voltage Options: 12V DC, 24V DC, 110V AC, 230V AC

Key Features

- Reliable Operation:

- Designed for precise control with immediate response and minimal lag, ensuring efficient operation in critical applications.

- Durable Construction:

- Made from stainless steel and other high-grade materials, ensuring resistance to corrosion and wear even in harsh environments.

- Energy Efficient:

- Operates with low power consumption, providing energy savings over time without compromising performance.

- Customizable Options:

- Various seal materials and configurations available to suit specific application needs.

Applications

- Compressed Air Systems: Ideal for controlling air flow in pneumatic systems, ensuring stable operation.

- Water Treatment: Provides reliable control for the regulation of water flow in treatment plants.

- Food & Beverage: Meets sanitary standards for controlling liquid and gaseous media in food processing.

- Chemical Processing: Suitable for controlling the flow of chemicals in manufacturing processes.

Benefits

- Compact Design: Easily integrates into tight spaces, reducing the need for complex installations.

- Durable: Resistant to wear and tear, providing a long service life even in challenging conditions.

- Precise Control: Offers fine control over media flow for applications that require accuracy.

15. Pinch Type Solenoid Valve

Uflow Pinch Type Solenoid Valve

Pinch type solenoid valves are specifically designed for handling media that may contain suspended solids or particles. They are highly effective for controlling the flow of fluids in industries where contamination or clogging is a concern.

Specifications

- Port Size: 1/4″ to 2″

- Body Material: Stainless Steel, PP (Polypropylene), PVC

- Seal Material: EPDM, Nitrile (NBR), FKM (Viton)

- Operating Temperature: -30°C to 90°C

- Pressure Range: 0 to 10 Bar

- Voltage Options: 12V DC, 24V DC, 110V AC, 230V AC

Key Features

- Pinch Technology:

- The valve uses a flexible elastomeric tube that “pinches” to control the flow of media, offering an effective way to prevent contamination and clogging.

- Corrosion Resistance:

- Construction materials such as stainless steel, PVC, and polypropylene provide excellent resistance to corrosion and chemical degradation.

- Efficient Performance:

- Suitable for a variety of media, including abrasive and highly viscous fluids, ensuring smooth operation and minimal maintenance.

Applications

- Water Treatment: Used in water filtration and treatment processes for controlling flow without contaminating the system.

- Food & Beverage: Suitable for handling beverages, juices, or other food-related liquids.

- Chemical Industry: Ideal for use in systems involving chemicals or abrasive materials.

Advantages

- Low Maintenance: Simple construction and self-cleaning properties reduce maintenance requirements.

Versatile: Capable of handling a variety of challenging fluids, including slurries and abrasive liquids.

16. Direct Acting Media Separated Solenoid Valve

Uflow Direct Acting Media Separated Solenoid Valve (NC/NO)

This valve is designed for situations where direct contact with the media is not possible due to chemical or temperature concerns. The media separation ensures that the solenoid and internal components are isolated from the media flow, providing extended lifespan and reliability.

Key Features

- Media Separation:

- Ensures no direct contact between the media and solenoid, extending the lifespan of the valve.

- Durability:

- Corrosion-resistant materials and separation technology make this valve ideal for aggressive applications.

- Reliability:

Suitable for use in extreme temperature and pressure environments, ensuring dependable performance.

17. Gantry Solenoid Valve

2/2 Solenoid Valve for Terminal / Gantry Automation (NC / NO) – DAR Series

The DAR Series 2/2 solenoid valve is specifically designed for terminal and gantry automation systems, where it is used to control the flow of flammable and non-flammable liquids. This valve offers robust performance in demanding environments, especially in high-temperature and high-pressure applications like fuel management and chemical processing.

Valve Specifications:

- Port Size: 1/4” NPT(F)

- Body Material:

- SS316 (Standard for high corrosion resistance)

- SS304 (Optional)

- Seal & O-Ring Material: Viton GLT (Fluoroelastomer, designed for extreme temperature resistance)

- Media Temperature Range: -30°C to 230°C

- Media Compatibility: Petrol, Diesel, SKO (Superior Kerosene Oil), HSD (High-Speed Diesel)

- Model Numbers:

- D6J146NNVW035C1V0

- D6J144NZVW030C1V0

- Valve Position Options: Normally Closed (NC), Normally Open (NO)

- Orifice Size:

- 3.5 mm (Model-specific)

- 3 mm (Model-specific)

- Pressure Range:

- 0 to 21 bar (Model-specific)

- 0 to 18 bar (Model-specific)

- Ambient Temperature: -20°C to 70°C

Coil Specifications:

- Coil Features:

- High reliability, unaffected by voltage surges.

- Coils are easy to replace and lockable in 4×90° positions or freely movable.

- Coil Housing Options:

- IP65 Epoxy square coil (standard industrial use)

- IP65 Metallic round enclosure (additional protection)

- IP67 Flameproof enclosure (for hazardous environments)

- IP68 Weatherproof enclosure (for outdoor use in harsh conditions)

- Operating Voltage: 230V AC

- Power Consumption: 9W

Key Features:

- High-Temperature and Corrosion Resistance:

- Made from SS316 or SS304 with Viton GLT seals, the valve can withstand temperatures up to 230°C and is ideal for corrosive and high-temperature environments.

- Wide Pressure Range:

- Efficient operation within pressure ranges up to 21 bar, catering to high-pressure applications.

- Versatile Coil Housing Options:

- Multiple housing types to suit various environments, from standard industrial to hazardous and outdoor conditions.

- Direct Acting Design:

- Provides immediate operation without requiring a pressure differential, offering precise flow control.

- Compact and Reliable:

- Ideal for terminal automation systems where space is limited but reliability is critical.

- Customizable Configurations:

- Available in Normally Closed (NC) and Normally Open (NO) variants for specific application needs.

Applications:

- Terminal Automation Systems:

- Controls fuel flow in storage and loading terminals.

- Gantry Automation:

- Ensures reliable operation in gantry systems managing petrol, diesel, and other fuels.

- Petroleum and Chemical Industry:

- Handles high-temperature and flammable media like petrol, diesel, and kerosene.

- Diesel and Oil Distribution Systems:

- Facilitates the safe and efficient control of HSD and other oils.

- High-Pressure Fuel Systems:

- Accurate flow control for fuel systems operating under high pressure.

Advantages:

- Safety-Oriented Design:

- Flameproof and weatherproof coil options ensure safe operation in hazardous environments.

- Broad Temperature and Pressure Handling:

- Operates across a wide range of temperatures (-30°C to 230°C) and pressures (up to 21 bar), adaptable for demanding applications.

- Durable and Corrosion Resistant:

- Built with high-quality SS316 construction and Viton GLT seals, ensuring long service life in harsh conditions.

- Easy Maintenance:

- Modular design allows quick coil replacement, reducing downtime.

Recommendations:

- Filter Usage:

- It is recommended to use a filter at the inlet port to prevent debris from affecting valve operation.

18. 4×2 Double Solenoid Valve

Solenoid valves are vital in industries requiring precise fluid and gas control. With various configurations and materials, they meet the diverse needs of automation, manufacturing, and process control. Key features include corrosion resistance, flexible connections, and suitability for a wide range of media and operating conditions.