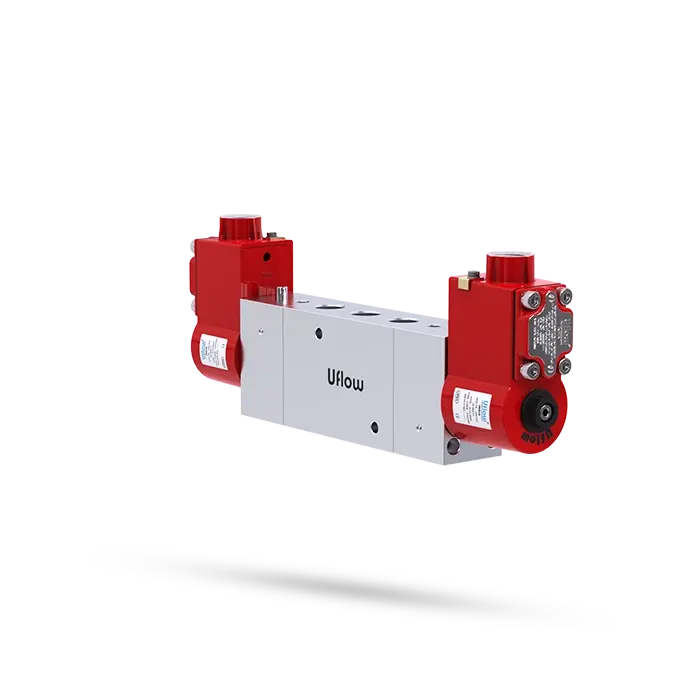

5X2 Double Solenoid Directional Control Integrated Poppet Valve

5X2 Double Solenoid Directional Control Integrated Poppet Valve – DCI Series

The DCI Series 5X2 Double Solenoid Poppet Valve is a high-performance, pilot-operated directional control valve designed for precise and reliable pneumatic switching. With its robust construction, high flow capacity, and flameproof coil housing, this valve is ideal for industrial automation, pneumatic actuation, and process control applications.

Valve Specifications

- Valve Type: 5X2 Double Solenoid

- Design: Internal Pilot Operated Poppet Valve

- Port Size: ½” BSP (Available in NPT)

- Media: Compressed Air (Filtered & Lubricated)

- Orifice Size: 12 mm

Pressure & Temperature Ratings

- Working Pressure Range: 2 – 10 bar

- Flow Factor: 50 Kv (LPM of Water @ 1 bar ΔP)

- Operating Temperature: 5°C – 60°C

Materials of Construction

- Body: SS316

- Seals: Nitrile

- Other Components: Polymer, Aluminium

Coil Information

- Operating Voltage & Power Consumption:

AC: 24V, 110V, 230V (9W)

DC: 24V (9W) - Coil Features:

High Reliability – Unaffected by voltage surges.

Easy Coil Replacement – Coil can be locked in 4X90° positions or freely movable as required. - Coil Housing: IP67 Flameproof Junction Box

Key Features & Benefits

High Flow Capacity – 50 Kv flow factor ensures efficient air control.

Fast & Reliable Switching – Internal pilot operation ensures rapid response.

Flameproof & IP67 Rated Coil – Safe for hazardous environments.

Durable Construction – SS316 & polymer components for corrosion resistance.

Easy Installation & Maintenance – Lockable coil design for flexible positioning.

Applications

Pneumatic Actuation – Controls cylinders, presses, and pneumatic machinery.

Industrial Automation – Used in material handling, conveyor systems, and robotics.

Process Control – Precise switching for fluid & gas handling systems.

Hazardous Environments – IP67 & flameproof coil for oil & gas, chemical plants, and mining.