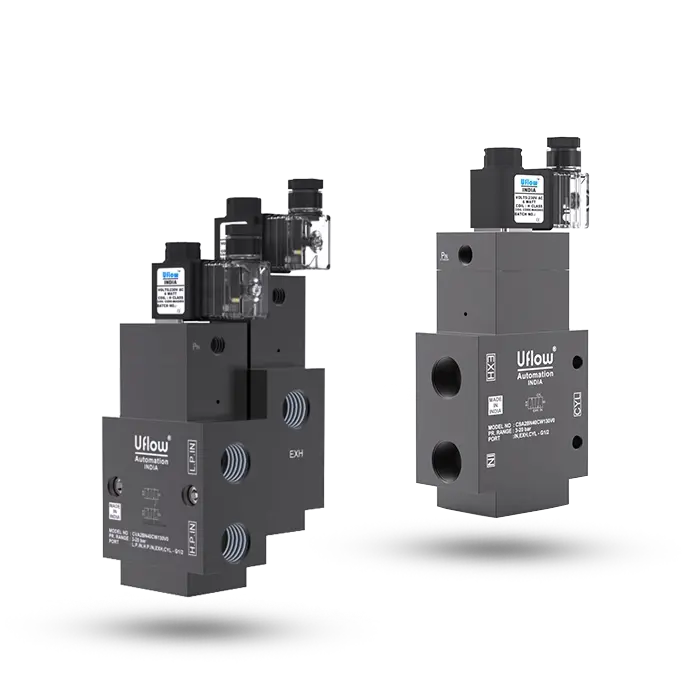

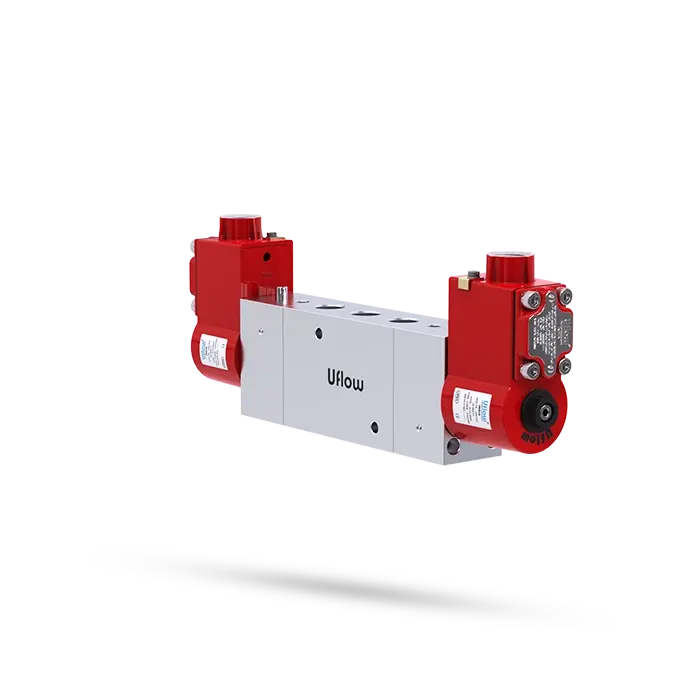

Poppet Valve

Poppet Valve

A Poppet Valve is a critical component used in a wide range of industrial and mechanical applications for controlling the flow of fluids and gases. The valve operates by lifting a solid, disc-shaped element (the poppet) off its seat, allowing fluid to pass through, or by seating it to block the flow. Here are the detailed specifications and features of a typical poppet valve:

Design and Construction

- Type: Poppet Valve

- Operation: Direct Acting

- Body Material: Commonly made from durable materials such as Aluminium, Brass, Stainless Steel, or Polymer.

- Seal Material: High-quality elastomers like Nitrile, EPDM, or Viton, ensuring leak-free operation.

Size and Connections

- Inlet/Outlet Ports: Available in various sizes such as 1/4″ BSP & NPT to fit standard piping systems.

- Orifice Size: Typically ranges around 5mm or larger, depending on the specific application and flow requirements.

Media Compatibility

- Media Types: Suitable for Compressed Air (Filtered & Lubricated), Water, Oil, and other compatible fluids and gases.

- Working Pressure Range: Can handle pressures from 0 to 10 Bar, ensuring versatility for different applications.

- Temperature Range: Ambient and media temperatures typically range from 5°C to 60°C, accommodating various operational environments.

Key Features

- Fast Response Time: Capable of rapid cycling, often up to 1000 cycles per minute, making it ideal for applications requiring quick operation.

- Manual Override: Provides the ability to manually operate the valve for testing or emergency purposes.

- High Durability: Designed to endure millions of cycles (e.g., tested up to 10 million cycles), ensuring long service life and reliability.

- Low Maintenance: Lubrication is not essential, reducing the need for regular maintenance and ensuring ease of use.

- Universal Configuration: Can be configured as Normally Open (NO) or Normally Closed (NC), offering flexibility for various control scenarios.

Applications

Poppet valves are widely used in numerous industries due to their reliability and efficient flow control capabilities. Common applications include:

- Pneumatic Systems: Used in automation, manufacturing, and robotic systems to control the flow of compressed air.

- Hydraulic Systems: Employed in machinery and equipment to regulate hydraulic fluid flow.

- Process Control: Essential in chemical processing, food and beverage production, and pharmaceuticals for precise fluid management.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems for regulating air flow.

- Automotive and Aerospace: Integral in engine systems for fuel and air control, and in various fluid management systems.

A poppet valve is a robust and versatile component that ensures reliable and precise control of fluid and gas flow. Its durable construction, rapid response time, and low maintenance requirements make it an ideal choice for a wide range of industrial applications. Whether in automation, process control, or HVAC systems, poppet valves provide efficient and long-lasting performance.