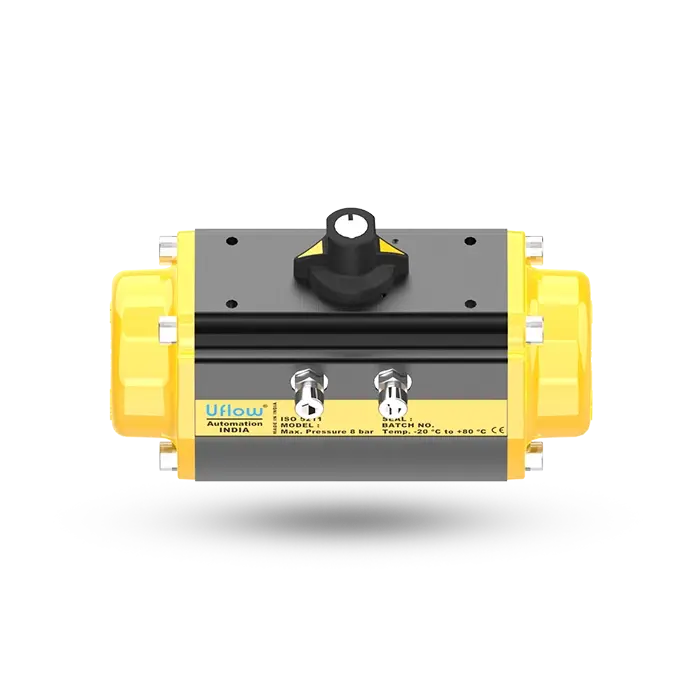

Pneumatic Actuator

Pneumatic Actuator

The Pneumatic Actuator is a high-performance device designed to provide reliable and efficient control for industrial automation processes. With robust construction and versatile operation modes, it ensures precise movement in various pneumatic systems.

Uflow Pneumatic Actuators – Single Acting & Double Acting (AD Series & AS Series)

Compact | Patented Design | High Efficiency

Uflow’s Pneumatic Rotary Actuators are engineered for precision control in valve automation systems, offering two efficient configurations—Single Acting (AS Series) and Double Acting (AD Series). With a patented aluminium-free rack & pinion mechanism, these actuators deliver reliable, smooth, and torque-optimized performance for various industrial applications.

1) Uflow Single Acting Pneumatic Actuator – AS Series

Fail-Safe Operation

The Single Acting actuator uses compressed air to operate in one direction and a spring return mechanism to revert the actuator to its original position when air pressure is removed—ideal for fail-safe or emergency shutdown applications.

Key Features:

Spring Return Mechanism – Ensures automatic closure in power loss or emergency situations

Low Air Consumption – Compact design minimizes air volume requirements

Hard Anodized Body – Superior corrosion and wear resistance

Smooth Stroke Movement – Reduces stress on valve seals and seats

Maintenance-Free Design – Long service life with minimal servicing

Design Standard: ISO 5211

Certified: ATEX-compliant for use in hazardous areas

Technical Highlights:

Max Working Pressure: 8 bar

Temperature Range:

NBR: –20 °C to +80 °C

Viton: –20 °C to +125 °C

Fluorosilicone: –60 °C to +110 °C

Stroke Adjustment:

+5° Overtravel for opening

–5° Undertravel (adjustable)

Air Volume Efficiency: Uses significantly less air than competing brands

2) Uflow Double Acting Pneumatic Actuator – AD Series

Bidirectional Control

The Double Acting actuator uses air pressure to move in both directions, providing high torque output and control precision for critical valve operations.

Key Features:

High Torque in Both Directions – Precise actuation for open/close operations

Compact & Lightweight – Ideal for limited space applications

Low Air Volume Usage – Energy-efficient operation

Anodized Aluminium Housing – Long-lasting protection against wear and corrosion

Smooth, Jerk-Free Motion – Enhanced valve life and operational accuracy

Design Standard: ISO 5211

Certified: ATEX-approved

Technical Highlights:

Max Working Pressure: 8 bar

Temperature Range:

NBR: –20 °C to +80 °C

Viton: –20 °C to +125 °C

Fluorosilicone: –60 °C to +110 °C

Stroke Adjustment:

+5° Overtravel

–5° Undertravel (adjustable)

Applications for Both Models

Valve automation in oil & gas, chemical plants, power stations, water treatment, pharmaceuticals, and food processing

Ideal for ball valves, butterfly valves, and plug valves

Suitable for automated control systems, remote actuation, and safety shutdowns

Why Uflow Actuators?

Patented Aluminium-Free Design – Lightweight and wear-resistant

Compact Yet Powerful – Low air consumption with high torque

Global Standards Compliance – ISO 5211 mounting & ATEX-certified

Long Service Life – Minimal maintenance requirements