Single Acting Y- Control Valve

Single Acting Y- Control Valve

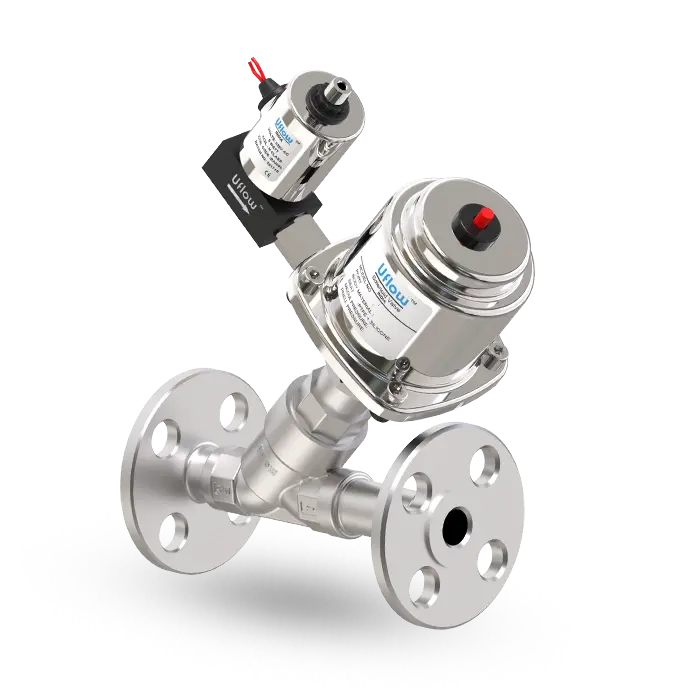

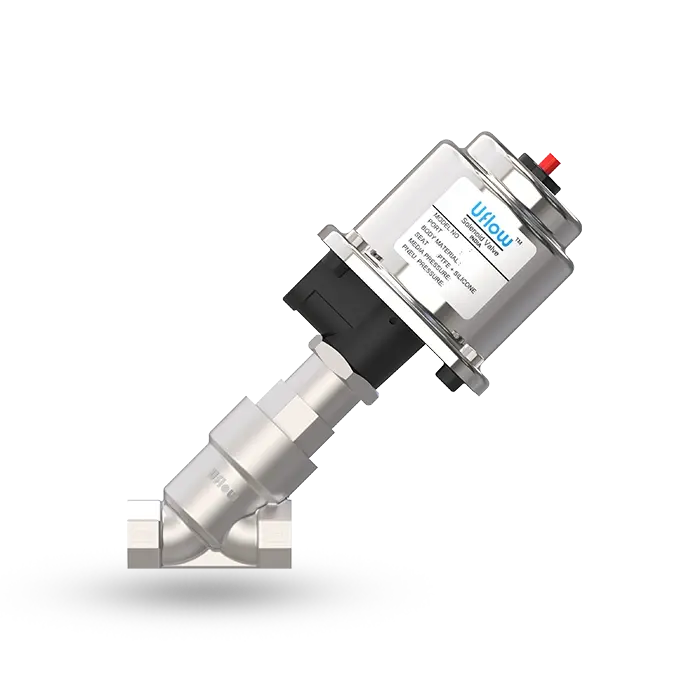

Angle Seat Valve with Steel Actuator Operator (NC / NO) – YCP Series

The YCP Series Angle Seat Valve is designed for high-performance flow control in demanding industrial applications. With a stainless steel body and a durable actuator, it provides precise, reliable, and long-lasting operation. The valve is available in Normally Closed (NC) and Normally Open (NO) configurations to suit various system requirements.

Valve Specifications

- Port Sizes: ½”, ¾”, 1”, 1¼”, 1½”, 2”, 2-1/2”

- End Connections: Screwed / Flange / Tri-Clamp / Socket Weld

- Body Material: SS ASTM A351 Grade CF8 / CF8M / CF3M

- Seal Options: PTFE / VITON

- Ambient Temperature Range: -10°C to 70°C

- Media Temperature Range: -10°C to 180°C

- Media Compatibility:

- Steam

- Air

- Water

- Chemicals

- Gases

- Oil

- Diesel

- Hot Water

Actuator Specifications

- Cover Material: SS304 Stainless Steel

- Plate Material: Aluminum Die-Cast

- Working Pressure: 3.5 to 7 bar air

(Not recommended for pneumatic pressure above 7 bar) - Cycle Life: More than 10 million cycles

- Additional Features (Available on Request):

- Stroke Limiter Adjustment

- Position Sensor Integration

Applications

The YCP Series Angle Seat Valve is ideal for high-flow applications where fast, reliable, and leak-proof performance is essential. It is widely used in:

- Steam and Hot Water Systems – Effective control for industrial heating and sterilization.

- Chemical & Pharmaceutical Industries – Handles aggressive chemicals and gases safely.

- Food & Beverage Processing – Suitable for CIP (Clean-in-Place) and SIP (Sterilization-in-Place) applications.

- Pneumatic & Compressed Air Systems – Ensures efficient flow regulation.

- Oil & Gas Industry – Manages high-temperature and high-pressure fluids.

- Water Treatment & Filtration – Controls fluid direction and pressure in purification systems.

Key Features & Benefits

– Durable Stainless Steel Construction – Corrosion-resistant and ideal for harsh environments.

– High-Temperature Resistance – Handles media up to 180°C.

– Fast & Reliable Actuation – Supports over 10 million cycles for long-term use.

– Self-Adjusting Seal Design – Reduces maintenance and ensures leak-tight performance.

– Flexible Installation Options – Available with screwed, flange, tri-clamp, and socket weld connections.

– Position Sensor & Stroke Limiter Available – For enhanced control and precision.

– NC & NO Configurations Available – Provides versatility for different system requirements.