Pneumatic Valves

Pneumatic Valves

Pneumatic Valves, Solenoid Valves, Poppet Valves, Dust Collector, Y- Control Valve, Ball Valve with Actuator, Solenoid Coils, FRL, Moisture Separators, Pneumatic Hand Lever Valves, Pneumatic Air Guns, Diaphragm Control Valve – S.R. Associates

1) Solenoid Valves:

Solenoid valves are electromechanically operated valves used to control the flow of air or other gases in pneumatic systems. They consist of a solenoid coil and a valve body with an actuator mechanism. When the coil is energized, it generates a magnetic field that opens or closes the valve, allowing or blocking the flow of air.

2) Poppet Valves:

Poppet valves are commonly used in pneumatic systems to control the flow of air. They feature a cylindrical or conical plug (poppet) that moves up and down to regulate airflow. Poppet valves are known for their reliability and versatility in various pneumatic applications.

3) Dust Collector Valves:

Dust collector valves are specifically designed for use in dust collection systems to control the flow of air and collect dust particles. These valves help maintain air quality and prevent dust buildup in industrial environments.

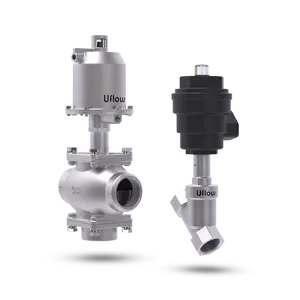

4) Angle Seat Valves/Y-Control Valves:

Angle seat valves, also known as Y-control valves, are pneumatically operated valves used to control the flow of air or liquids at an angle to the pipe axis. They feature a piston-like actuator that moves perpendicular to the flow path, allowing for precise flow control.

5) Ball Valve with Pneumatic Actuator:

Ball valves equipped with pneumatic actuators are used to control the flow of air or liquids in pneumatic systems. The actuator rotates the ball inside the valve body to open or close the flow path, providing reliable on/off control in various industrial applications.

6) Butterfly Valve with Pneumatic Actuator:

Butterfly valves with pneumatic actuators are commonly used in pneumatic systems for regulating airflow. The actuator rotates a disc, called a butterfly, to control the flow of air through the valve body.

7) Solenoid Coils:

Solenoid coils are electrical coils used in solenoid valves to generate a magnetic field when energized. This magnetic field actuates the valve, controlling the flow of air or fluids in pneumatic systems.

8) Pneumatic Actuators:

Pneumatic actuators are devices that convert pneumatic energy into mechanical motion to control valves, dampers, or other mechanical components in pneumatic systems. They are widely used for remote or automated operation of valves in industrial applications.

9) Micro Limit Switches:

Micro limit switches are small, precision switches used to detect the position of mechanical components, such as valve actuators, in pneumatic systems. They provide feedback to control systems for precise positioning and operation.

10) Filter, Regulator & Lubricator (FRL):

FRL units are essential components in pneumatic systems, providing filtration, pressure regulation, and lubrication of compressed air. They ensure clean, dry, and properly regulated air supply to pneumatic components, enhancing system performance and longevity.

11) Rotoseal Couplings:

Rotoseal couplings are mechanical seals used to connect rotating shafts in pneumatic systems, providing a leak-proof and secure connection while allowing for rotational movement. They are commonly used in rotary pneumatic actuators and valves.

12) Moisture Separators:

Moisture separators are devices used to remove moisture or condensate from compressed air in pneumatic systems. They help prevent corrosion, improve system efficiency, and protect downstream components from damage.

13) Pneumatic Hand Lever Valve:

Pneumatic hand lever valves are manually operated valves used to control air flow in pneumatic systems. They feature a lever or handle that, when actuated, opens or closes the valve to regulate airflow manually.

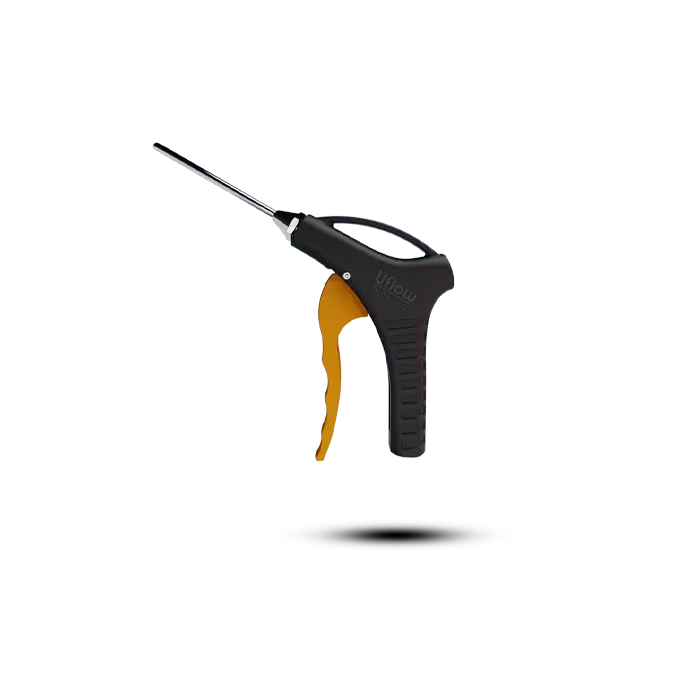

14) Pneumatic Air Guns:

The Air Blow Gun is a compact and efficient tool designed for precision cleaning, drying, and dust removal in industrial and workshop environments.

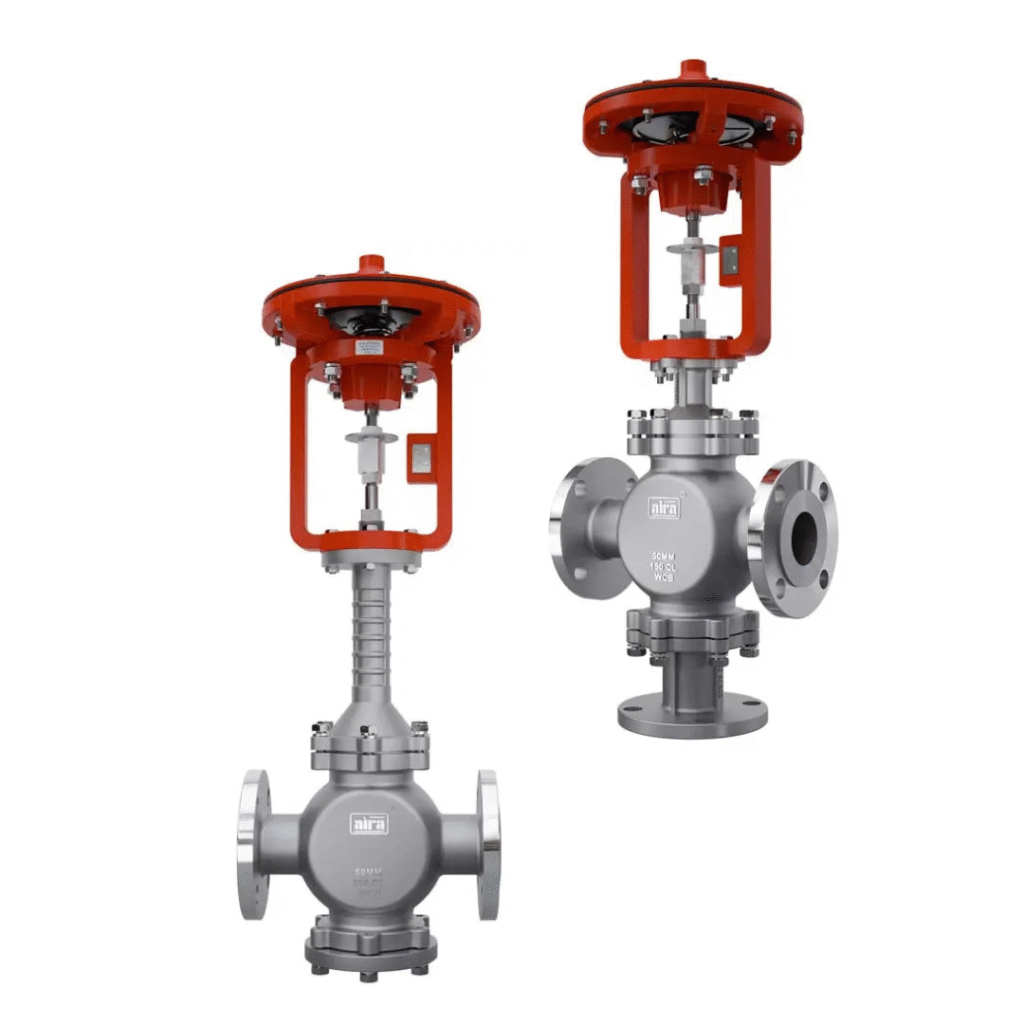

A diaphragm operated control valve is a pneumatically actuated valve designed for precise on/off or modulating flow control of fluids like steam, gas, water, or thermic fluid. It offers reliable performance in high-temperature and high-pressure applications, with minimal leakage and low maintenance.