Pneumatic Tie Rod Cylinder

Pneumatic Tie Rod Cylinder

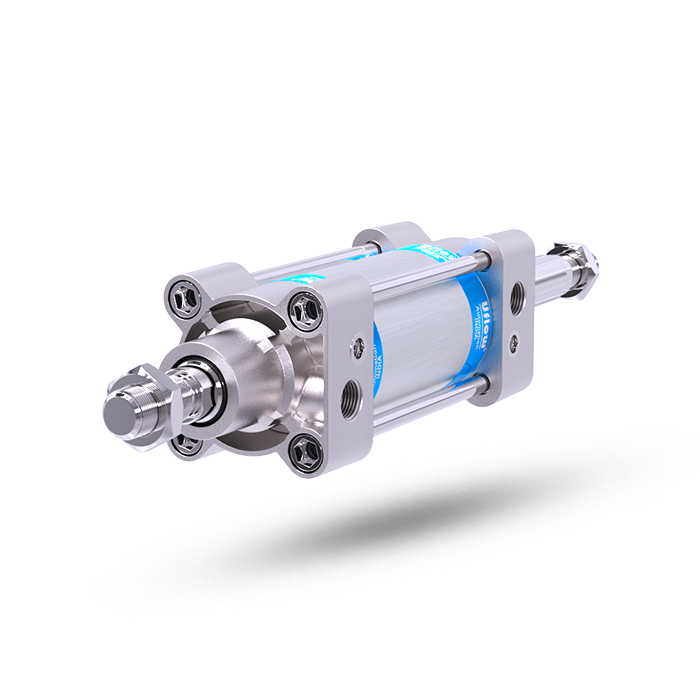

Pneumatic Tie Rod Cylinder – CS4 Series (ISO 15552 / VDMA 24562 Compliant)

The CS4 Series Pneumatic Tie Rod Cylinder is built for high performance, durability, and precision in industrial applications. Designed in compliance with ISO 15552 / VDMA 24562 standards, it ensures global interchangeability, easy integration, and operational efficiency in automation systems.

Technical Specifications

Cylinder Bore Sizes (Ø mm)

32, 40, 50, 63, 80, 100, 125, 160, 200, 250

Cushion Stroke (mm)

- 32mm – 21mm

- 40mm – 23mm

- 50mm – 23mm

- 63mm – 23mm

- 80mm – 28mm

- 100mm – 28mm

- 125mm – 40mm

- 160mm – 40mm

- 200mm – 40mm

- 250mm – 50mm

Standard Stroke Lengths (mm)

25, 50, 80, 100, 125, 160, 200, 250, 300, 320, 400, 500

Operating Conditions

- Media: Compressed Air (Filtered & Lubricated)

- Working Pressure: 0.5 – 10 bar

- Ambient Temperature: -10°C to +70°C

Medium Temperature

Regular Applications: +5°C to +60°C

High-Temperature Applications: +5°C to +150°C

Materials of Construction

- Cylinder Body & End Caps: Aluminium

- Piston Rod & Tie Rods: Steel

- Seals: Polyurethane, Nitrile (Regular), FKM (High-Temperature)

- Bushings & Bearings: Brass, Acetal

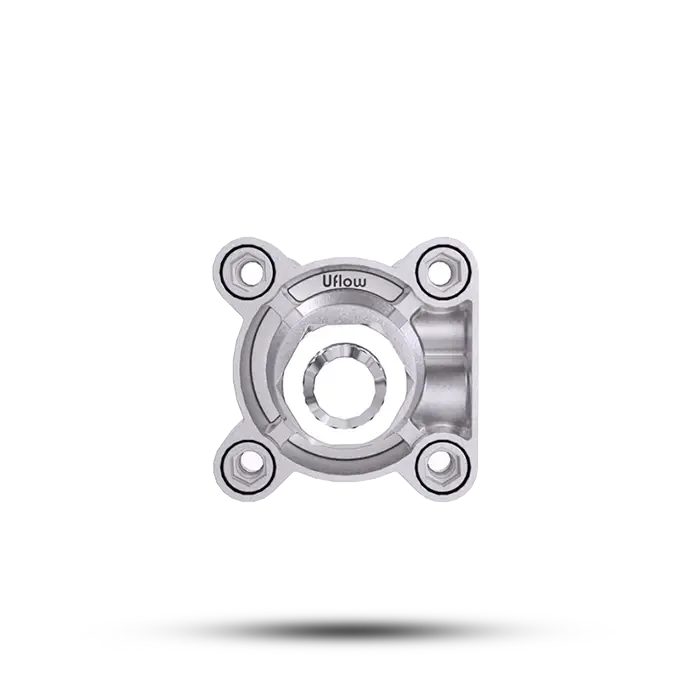

Mounting Options

The CS4 Series offers multiple mounting configurations for seamless integration:

- Foot Mounting

- Front / Rear Flange

- Male Clevis

- Female Clevis

- Center Trunnion

- Front Trunnion

- Rear Trunnion

Accessories

Enhance installation and adaptability with the following available accessories:

- Clevis Foot Bracket

- Wall Mounting Bracket

- Trunnion Bracket

- Rod End Fork

- Rod End Aligner

- Rod End

- Spherical Eye

Key Features & Benefits

- ISO 15552 / VDMA 24562 Standard Compliant – Ensures global compatibility & interchangeability.

- High Durability – Aluminium body with corrosion-resistant steel components for extended service life.

- Precision Cushioning – Optimized cushion stroke for smooth operation & shock absorption.

- Versatile Installation – Multiple mounting options for easy system integration.

- Extended Temperature Range – Up to +150°C for high-temperature applications.

- Customizable Strokes – Standard & extended stroke lengths available for various applications.

- Optimized Sealing System – Prevents leaks & enhances performance in demanding environments.

Applications

- Industrial Automation & Robotics – Precise actuation in automated machinery.

- Material Handling & Packaging – Efficient linear motion control.

- Process Control & Pneumatics – Reliable operation in compressed air systems.

- Machine Tools & Automotive – Durable actuation for heavy-duty applications.

- Textile & Food Processing – Hygienic & corrosion-resistant materials available.

Pneumatic Tie Rod Cylinder – S.R. Associates | Uflow Pneumatic Tie Rod Cylinder, Uflow Tie Rod Cylinder, Uflow Pneumatic Cylinders, Uflow Cylinders