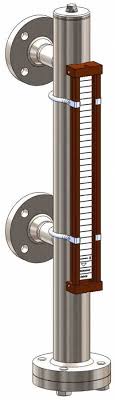

Magnetic Level Indicators

Magnetic Level Gauges

A Magnetic Level Gauges is a device used for visually monitoring the level of a liquid in a container or vessel. It utilizes the principles of magnetism to provide a continuous and reliable indication of fluid levels. Here’s a general description of a magnetic level indicator:

Basic Components:

Float: The MLI typically includes a float, which is a buoyant device that moves up and down with the liquid level. The float contains magnets or magnetic strips.

Magnetic Level Indicator Chamber: This is a transparent or translucent chamber mounted externally on the side of the vessel. It contains a magnetic float that rises and falls with the liquid level inside the vessel.

Indicator Board or Scale: Located on the exterior of the chamber, it provides a visual reference for the liquid level. The scale is often calibrated in units of measurement relevant to the specific application.

Flag or Indicator: A visual indicator, often a brightly colored flag or marker, moves in conjunction with the float, providing a clear indication of the liquid level.

Magnetic Coupling:

The float inside the chamber contains magnets or magnetic strips, and as it moves with the changing liquid level, it influences the position of an external indicator on the chamber.

The magnetic field created by the float is transmitted through the chamber wall to an external visual indicator, eliminating the need for direct contact between the indicator and the process fluid.

Continuous Level Monitoring:

Magnetic level indicators offer continuous level monitoring without the need for power or electrical connections. This makes them reliable in various industrial settings, including those with hazardous conditions.

Suitability for Various Fluids:

MLIs are suitable for use with a wide range of fluids, including corrosive, high-temperature, and high-pressure substances. The materials used in the construction of the chamber are often chosen to withstand the properties of the monitored fluid.

Application in Various Industries:

Magnetic level indicators find applications in industries such as chemical processing, oil and gas, water treatment, pharmaceuticals, and more, where accurate and reliable liquid level monitoring is critical for operational efficiency and safety.

Maintenance and Installation:

Magnetic level indicators are generally easy to install and require minimal maintenance. The absence of moving parts within the process fluid contributes to their reliability.

Optional Accessories:

Some MLIs may come with additional features, such as alarms, transmitters, or switches, allowing for integration with control systems or providing alerts when certain level conditions are met.

Overall, magnetic level indicators provide a simple and effective means of visually monitoring liquid levels in a variety of industrial applications. They are valued for their reliability, accuracy, and versatility.