Acrylic Tubes

Acrylic Tubes

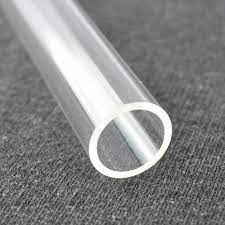

Acrylic tubes are cylindrical structures made from acrylic, a thermoplastic known for its clarity, durability, and versatility. These tubes are commonly used in various applications across industries due to their transparent nature, which allows for easy visibility of contents, and their ability to be easily shaped and fabricated.

Material Composition: Acrylic tubes are typically made from polymethyl methacrylate (PMMA), which is a synthetic polymer also known by the trade names Perspex, Plexiglas, and Lucite. PMMA is a transparent thermoplastic that can be molded into various shapes.

Clarity: One of the main advantages of acrylic tubes is their optical clarity. They offer excellent transparency, allowing light to pass through with minimal distortion. This makes them suitable for applications where visibility or display of content is important.

Durability: Acrylic tubes are known for their durability and resistance to impact. They are less likely to shatter than glass, making them a safer option in certain applications.

Lightweight: Acrylic is a lightweight material, making acrylic tubes easy to handle and transport. This property is particularly beneficial in applications where weight is a consideration.

Versatility: Acrylic tubes can be easily machined, cut, and shaped to meet specific design requirements. This versatility allows for customization to suit a wide range of applications.

Weather Resistance: Acrylic is resistant to the damaging effects of ultraviolet (UV) radiation, making it suitable for outdoor applications. However, prolonged exposure to UV rays can cause gradual yellowing over time.

Chemical Resistance: Acrylic has good resistance to many chemicals, although it may be affected by certain solvents. It’s important to consider the specific chemical environment when choosing acrylic tubes for a particular application.

Temperature Resistance: Acrylic has a moderate temperature resistance and may soften or deform at high temperatures. It is important to consider the intended operating temperature range when using acrylic tubes.

Applications: Acrylic tubes find applications in a variety of industries, including display and signage, lighting, arts and crafts, scientific research, aquariums, and more.

When using acrylic tubes, it’s essential to consider factors such as the diameter, thickness, and length of the tube based on the specific requirements of the application. Additionally, protective coatings or treatments may be applied to enhance scratch resistance or UV stability, depending on the intended use.