Toggle Clamp

Toggle Clamp

A Toggle Clamp is a mechanical device that holds objects securely in place by applying a clamping force through a pivot and linkage mechanism. It is widely used in industrial applications where fast and repeatable clamping is required.

Types of Toggle Clamps

- Horizontal Toggle Clamp – Features a horizontal handle that locks parallel to the base.

- Vertical Toggle Clamp – Handle locks in a vertical position, suitable for space-constrained setups.

- Push-Pull Toggle Clamp – Linear action clamp that moves forward and backward to hold objects.

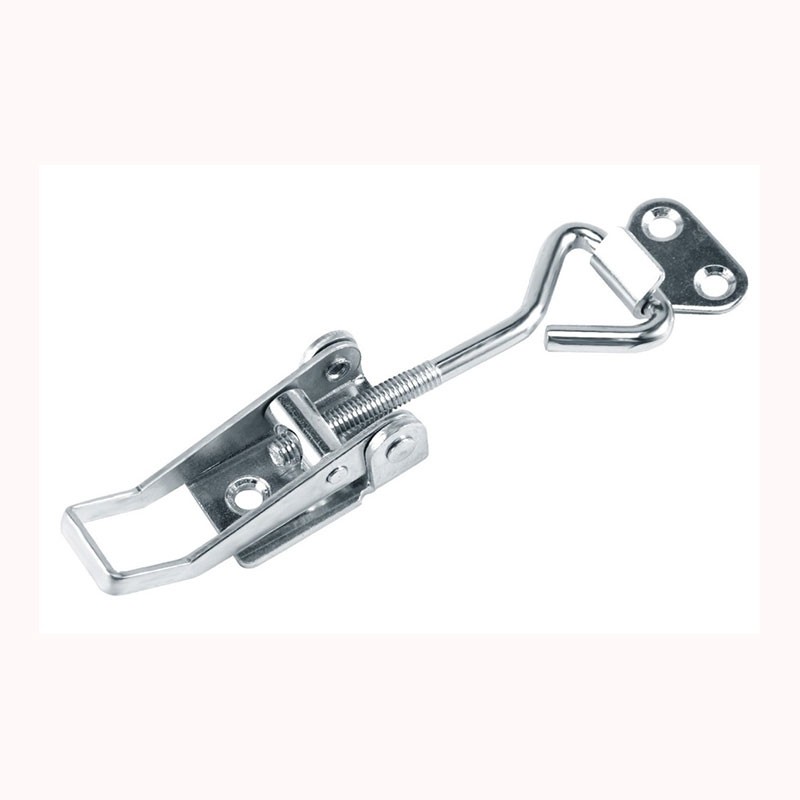

- Latching Toggle Clamp – Used for securing lids, doors, or panels with a hook-and-latch mechanism.

- Heavy-Duty Toggle Clamp – Designed for high-force applications requiring strong clamping.

Key Features

- Quick Clamping & Release: Fast action lever for easy and rapid operation.

- Secure Locking Mechanism: Provides firm holding force to prevent movement.

- Ergonomic Handle: Comfortable grip for ease of use.

- Durable Construction: Made from high-quality materials like steel, stainless steel, or aluminum for extended life.

- Variety of Holding Capacities: Available in different force capacities to suit light to heavy-duty applications.

Applications of Toggle Clamps

- Woodworking & Carpentry – Holds workpieces securely for cutting, drilling, and sanding.

- Metalworking & Welding – Ensures precise positioning during welding and metal fabrication.

- Automobile Manufacturing – Used in fixtures and jigs for assembling automotive parts.

- Plastic & Injection Molding – Keeps molds and parts firmly in place.

- Food Processing Equipment – Stainless steel toggle clamps are used for hygiene and safety compliance.

– High Clamping Force with Minimal Effort

– Repeatable and Reliable Performance

– Increases Productivity in Manufacturing & Assembly

– Reduces Operator Fatigue with Easy Operation

– Versatile Usage Across Various Industries

Toggle Clamps are an essential tool in manufacturing, automation, and assembly operations, ensuring efficiency, safety, and precision.