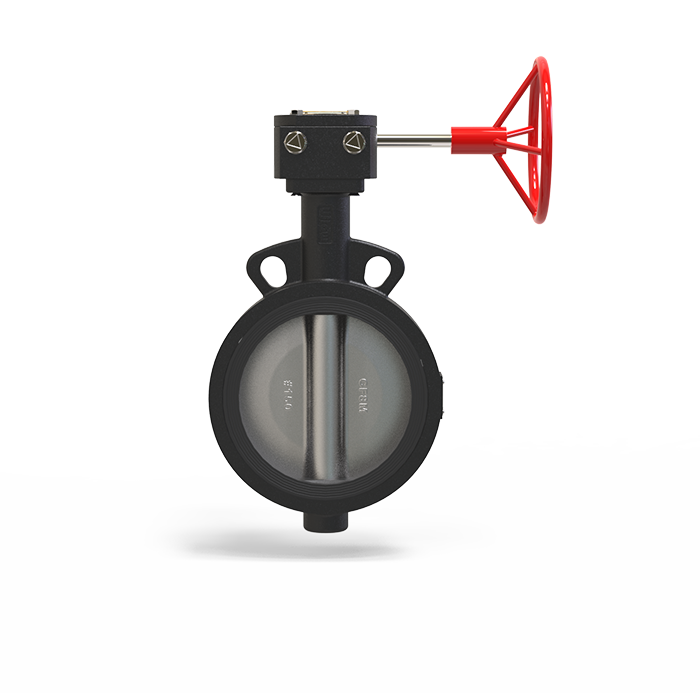

Butterfly Valves C.I. Body S.S. Disc Gear Operated

Butterfly Valves C.I. Body S.S. Disc Gear Operated

Size Range:

- These gear-operated butterfly valves are available in sizes ranging from 1.1/2″ to 12″. This flexibility allows them to be used in various pipe systems.

Materials:

- The valve bodies are typically made from S.G. Iron (Spheroidal Graphite Iron), Ductile Iron, or Stainless Steel (S.S.).

- S.G. Iron (Spheroidal Graphite Iron): Also known as ductile iron, S.G. iron provides excellent mechanical properties, including high tensile strength and impact resistance. It is commonly used in industrial applications.

- Ductile Iron: Similar to S.G. iron, ductile iron offers good strength and durability. It is resistant to corrosion and suitable for various environments.

- Stainless Steel (S.S.): The S.S. material (such as S.S. 304) provides excellent corrosion resistance, making it ideal for applications where exposure to corrosive fluids is a concern.

- The valve bodies are typically made from S.G. Iron (Spheroidal Graphite Iron), Ductile Iron, or Stainless Steel (S.S.).

Operation Types:

- Gear-operated valves can be operated using a gear mechanism. The gear allows precise control over the valve’s opening and closing.

- These valves are commonly used in industrial processes, water supply systems, and HVAC applications.

Features:

- Bi-Directional Operation: Gear-operated butterfly valves can control flow in both directions.

- Robust Construction: The materials used ensure durability and longevity.

- Mounting Options: These valves can be mounted between flanges according to standards such as ASME.

- Tested Performance: They undergo testing to ensure reliable performance.